Hotel and spa

Circuit-level monitoring for a hotel and spa complex.

Background

A prestigious hospitality establishment with a dedicated focus on environmental stewardship sought to reduce energy usage, carbon emissions and operational expenses.

A pilot project showed significant results, achieving 21% reduction in HVAC spending (ROI <6 months). With the concept proven, we installed additional sensors and supercharged the service.

Project goals

- Identify unnecessary waste to reduce costs and carbon emissions.

- Detailed understanding of energy use across the estate to maintain efficiency and improve sustainability.

Solutions

Easily installed Circuit-level Monitoring sensors quickly identified opportunities to reduce consumption and increase efficiency.

- Quarterly reviews between the client’s Facilities Manager and our energy experts evaluated performance metrics. We shared our insights and advised on site-specific modifications.

- The facilities manager used our user-friendly digital platform to analyse, target and report on their consumption data.

- We supplied & installed additional sensors to the air handling units (AHU).

Results

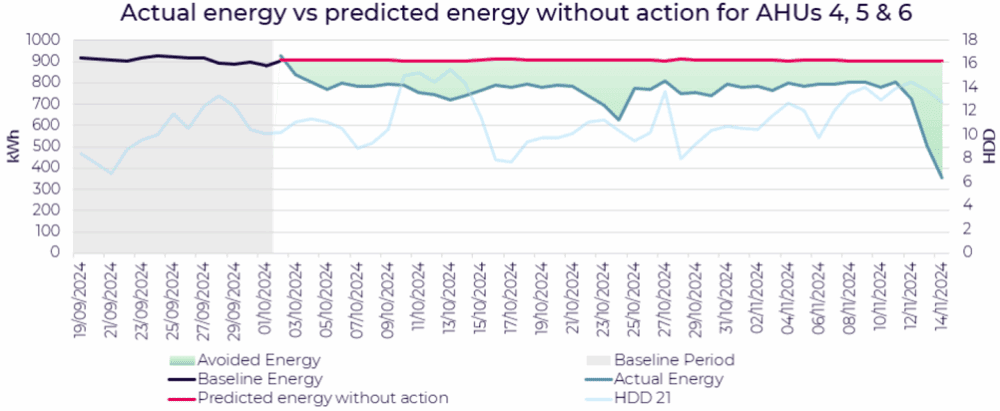

- To establish a baseline, AHU 4, 5, 6 sensor data was measured from 19 September to 1 October under the operational existing schedule.

- Analysis of AHU 4, 5, 6 usage patterns revealed high usage between 7am to 11pm. Subsequently, modifications were made to AHU’s scheduling to optimise costs while maintaining guest comfort.

- Operational changes were implemented from 2 October, programming the AHU to run in alternating on-off intervals of one hour within the 7am – 11pm timeframe.

Next Steps

Monitor consumption of other circuits in the hotel where CLM sensors are installed to pinpoint further optimisation of equipment settings to reduce cost and carbon emissions.

At a glance

savings in HVAC costs

54,505 kWh annual evergy savings

12.26 tCO2e annual carbon savings

CLM Savings Calculation

Annual Energy Savings: 54,505 kWh

Annual Carbon Savings: 12.26 tCO2e

CLM Installation

Equipment: 27 sensors, 4 bridges

Monitoring: AHUs, Laundry, Kitchen areas, Chillers

“The process was straightforward, with changes made quickly & effectively.”

Head of Facilities